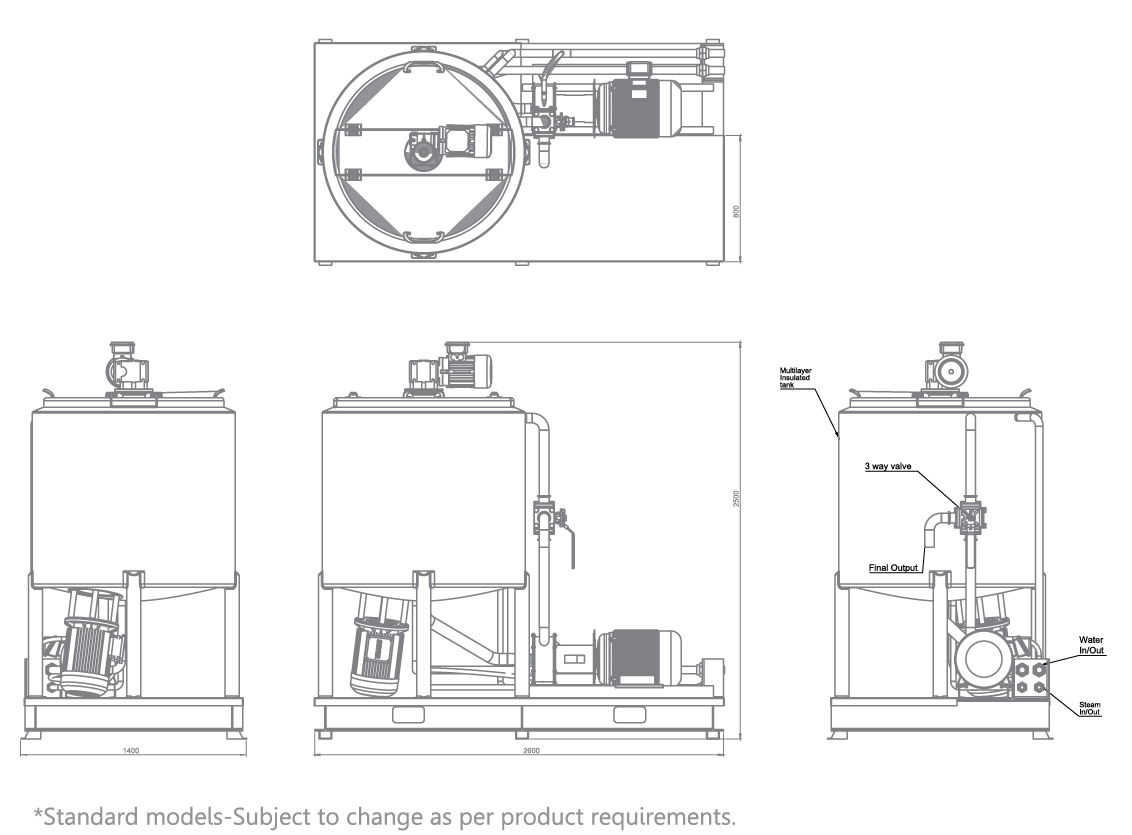

Our team of engineers have developed a Standard Mayo Maker. The unit is capable of carrying out the entire process, including rapid preparation of premixes, hydration of thickening and stabilising agents and preparation of the final oil-in-water emulsion.

The Standard Mayo Plant upholds a working capacity ranging from 500L/Hr to 1500L/Hr. Key factor being high-level product quality and productivity that can be validated in laboratory showing even distribution of particles and stable emulsion. It is a result of highly efficient and cyclic process including homogenizer and agitation tank. Raw material are agitated first in the tank and then passed through high shear homogenizer.

The standalone unit design approach is modernistic and state of art technology promises reduced production cost.