With rapidly growing population, needs of food industry are growing and there is always need of innovative technologies in process industry. Acknowledging the requirement, our team of engineers have developed a continuous production plant for manufacturing of mayonnaise and other emulsion foods encompassing advance technologies. The Automatic Mayo Plant upholds a working capacity ranging from 500L/hr to 5000L/hr.

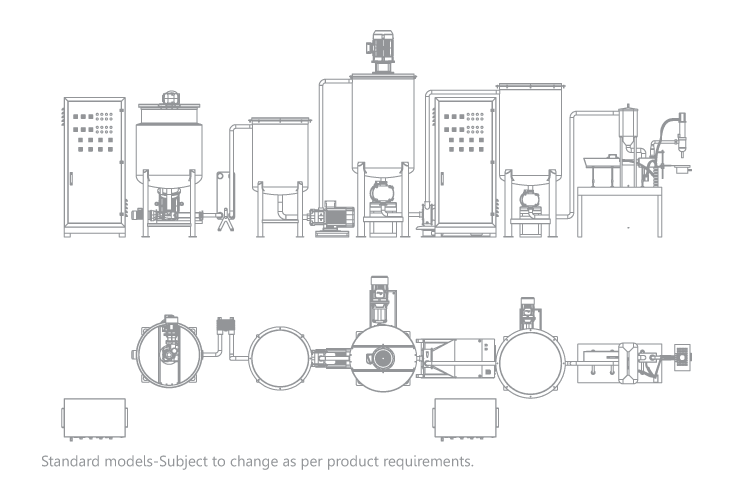

This is a fully automated system comprising of mixing tanks and buffer tanks that are highly compact. Despite this, the design allows cleaning and maintenance at ease.

The complete plant design approach is modernistic and state of art technology promises reduced cost.