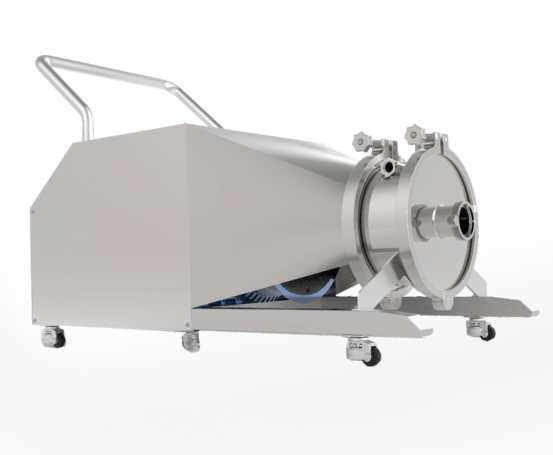

The high shear mixer homogenizer direct feed and discharge mechanism will reduce the production time by providing continuous feed of high quality product for further processes.

The mixer compromises of a rotor moving at high speed in a stationary part. The blades on the rotor create a centrifugal force that cuts the material as it passes through slots on the stator. The multistage rotor and cutting head provides intense cutting action with over 3 million individual cutting action in a second. The intense shear generated is enough to prepare all sorts of sauces and paste.