Ketchup process plant is contemporary idea of integrating different process machines together to maximise product quality and minimise energy consumption.

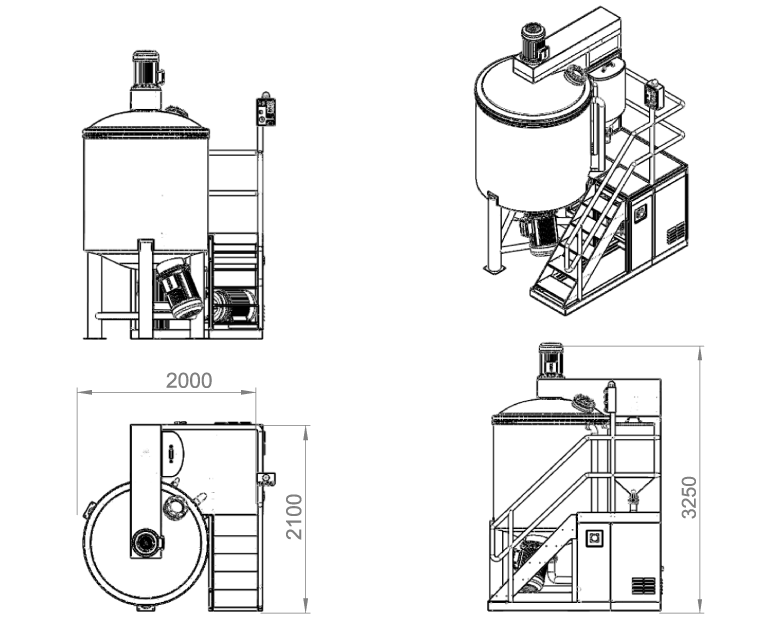

The ketchup manufacturing line encompasses a batch type homogenizing tank clubbed with a high shear inline mixer. The raw material is loaded into the mixing tank through the top.

The integrated in-line high shear mixer stimulates the process by emulsification of the material under process and circulating it through the cylinder. This machine is available with action of working under vacuum for maximum flavour retention in the product.