Mail Us

Call Us

+91 11- 49064625

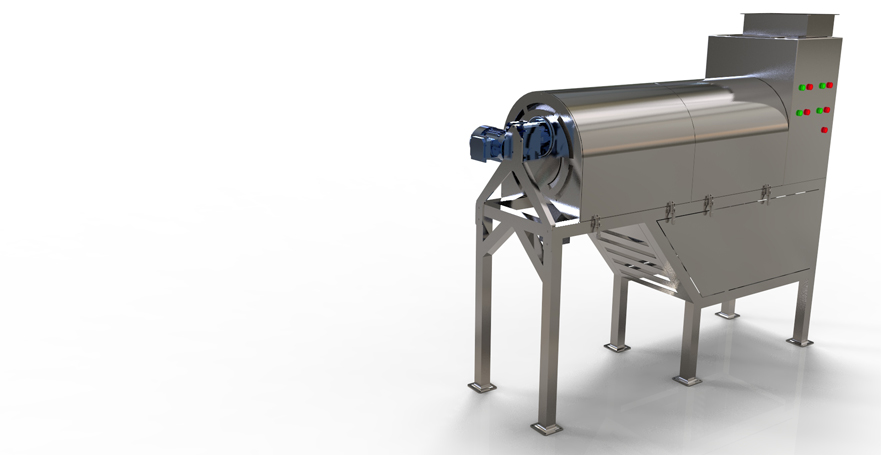

The CCD provides uniform and precise coating of ingredients over material in a continuous process avoiding product breakage.

Material is fed into rotating drum. Oil is sprayed over material in the form of mist through 4 high pressure nozzles before it enters rotating drum. The ingredients are fed through hopper into a screw conveyor which is placed at upper side of drum. The screw conveyor runs from one end to other of drum and evenly sprinkle the ingredients over its length. The rotating drum have internal screw which pushes the material forward. Additional impellers on internal screw enables the rotatory drum of thorough mixing. Final product is collected at the other of the drum through a funnel. Final product can be collected using a vessel or can be used for further processing in the line.

| Main Features | Optional |

| Minimum product breakage. Continuous coating process. Food safe oil-free compressor. All Hygienic Design SS304 Contact parts Ease of maintenance. Feed rate adjustment for ingredient. Speed Control. Uniform and precise coating Height Adjustable feet. Double Ball bearing Electrical Control and emergency shutdown. |

Electrically controlled valves PLC with HMI control. |

| Type | SMM 500 | SMM 1000 | SMM 1500 |

| Capacity(kg/hr) | 500 | 1000 | 1500 |

| Hopper Size(Main) | 70 | 150 | 200 |

| Hopper Size(Ingredients) | 20 | 50 | 75 |

| Drum Motor(Power) | 7.5HP | 10HP | 12.5HP |

| Ingredients Feeder Motor (Power) | 2.5HP | 4HP | 5HP |